Ngokuqhelekileyo, imingxuma enobubanzi obuyi-0.1mm-1.0mm ibizwa ngokuba yimingxuma emincinci. Uninzi lwezixhobo ezisetyenzisiweyo kwiindawo eziza kusetyenziswa zizinto ezinzima kumatshini, kubandakanywa i-carbide ene-cemented, insimbi engenasici kunye nezinye izinto ze-molecular composite, ngoko ke iintlobo ezahlukeneyo zetekhnoloji yokucubungula umngxuma omncinci, iindlela kunye nezixhobo ziye zaphuhliswa.

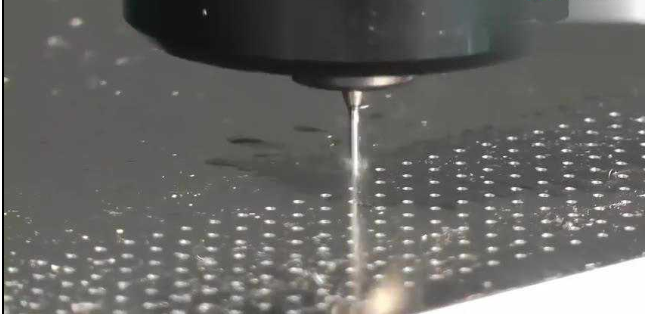

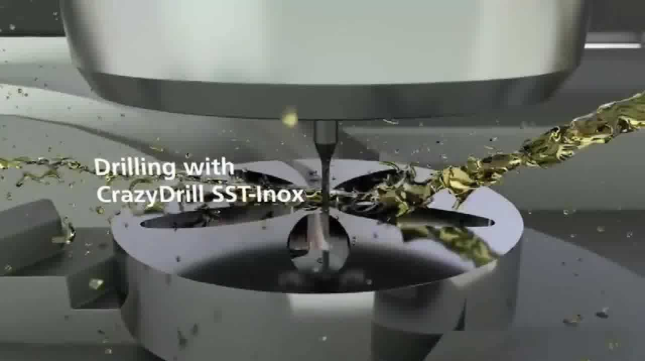

Phakathi kwabo, indlela yokwenza imingxunya emincinci yindlela yemveli yomatshini enembali ende, egqitywe ngezixhobo okanye i-drills, kwaye okwangoku isetyenziswa kakhulu.

Kwinkqubo enzulu yemigodi emincinci ekhankanywe ngasentla, isantya esihambayo se-drill bit kunye nesantya sokugaya sikhawuleza kakhulu, esifuna iimfuno eziphezulu zesixhobo somatshini kunye ne-drill bit.

Ukuba umsebénzi ufuna ukwenza umsebenzi omhle, kufuneka aqale azilole izixhobo zakhe. Xa ubhobhoza imingxuma emincinci ngeziko lomatshini, kungakhathaliseki ukuba luhlobo luni lomatshini olungileyo owusebenzisayo, kufuneka ube ne-drill elungileyo kuqala, akunjalo?

Kutheni abantu besenza imingxunya emincinci ngokukhawuleza nangokufanelekileyo?

Enye yamanqaku aphambili kumatshini omncinci wokwenziwa kulawulo lwetshiphu kunye nokusebenza kokukhutshwa kwetshiphu.

Ukulawulwa kwe-Chip: Ukusikwa kwe-drill kuqhutyelwa emngxunyeni kunye nesithuba esincinci, kwaye ii-chips kufuneka zikhutshwe kwi-groove ye-drill, ngoko ke imilo ye-chip inefuthe elikhulu ekusebenzeni kokusika kwe-drill. Iichips ezintle zivimba i-groove edge, zichaphazela ukuchaneka kokomba, kwaye zinciphisa ubomi be-drill bit; iitshiphusi ezinde zijijela i-drill bit, zithintele ukusebenza, zibangele ukuba i-drill bit yophuke okanye ithintele ulwelo lokusika ukuba lungene emngxunyeni.

Ukusebenza kokususwa kwe-chip: Ukuba indawo ye-chip yokususa i-groove ayinkulu ngokwaneleyo, ii-chips azikwazi ukukhutshwa ngokufanelekileyo, okuya kubangela ukuchaneka okungahambi kakuhle. Ngoko ke, kuyimfuneko ukwandisa indawo ye-chip flute ukufezekisa ukukhutshwa kwe-chips-free-barrier kunye nokuqinisekisa ukuzinza kokucubungula.

Enye into ephambili kwi-machining encinci yomngxuma yitekhnoloji yokwambathisa.

Iingubo zokwaleka zinyusa ukunxiba kwesixhobo kunye nokuxhathisa ubushushu, ngaloo ndlela zandisa ubomi besixhobo.

Ngoku, abaninzi abavelisi bezixhobo bayakuseta imingxuma yeoli yokupholisa yangaphakathi kwisibambi sesixhobo ukunceda ukonyusa ukuhamba kwesipholisi kunye nokunciphisa uxinzelelo lokupholisa. Xa ukupholisa kwamanzi kukhulu, iitshiphusi zinokukhutshwa ngokufanelekileyo kwaye umatshini ozinzileyo unokufezekiswa.

Ewe kunjalo, kukho iindlela ezininzi ngakumbi ngaphandle kokwenza imingxunya emincinci: njenge-EDM, i-electron beam, i-laser, i-laser ye-femtosecond, i-chemical etching kunye nokusika i-plasma, njl.

Ngokweminyaka emininzi yamava, umgangatho wokwenziwa komzi-mveliso unokuqondwa ngokulula ngokuya kwindlu yangasese kumzi-mveliso wabo. Le ndlela inokuthenjwa.

Kwinkqubo yokujongana neefektri, i-factory nganye iya kuzisa indlela ethembekileyo ngayo umgangatho weemveliso zayo kunye nendlela echanekileyo ngayo i-molds ... Awudingi ukuqonda kunye nokuvavanya kwinkalo yezobugcisa kuqala, kwaye siya kuthetha ngayo. kwigumbi lokuhlambela!

Ukuya kwezinye iifektri, imvakalelo yokuya kwindlu yangasese imnandi kakhulu. Ubume bendawo buqaqambile kwaye bucocekile, bubuhle kwaye bucocekile, indlu yangasese ixhotyiswe ngephepha lendlu yangasese, kukho isipili phambi kwesinki, isicoci sesandla siyafumaneka, kwaye itephu inamanzi ashushu nabandayo. Ngokwahlukileyo, ukuya kwindlu yangasese kwezinye iifektri kuyothusa ngokwenene kwaye ayichazeki. Uyazi, xa ufika kwigumbi lokuhlambela, uya kungena kwelinye ilizwe elimnyama.

Ixesha lokuposa: Oct-24-2022